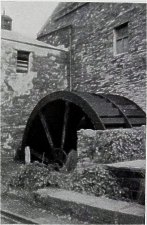

Fig. 1 [Laxey Old Mill]

By Waring S. Sholl, A.M.I.E.E.

Extremes certainly do meet in that charming little domain the Isle of Man, in which delectable spot the writer spent a few days a matter of a month or two ago. The Manx folk certainly have a good leaven of the stout Nordic stock in their make up. That is at onee discermble to those who are to same extent versed in primitive mill lore and the brains and imventive genius behind it.

The 13th century found the Norsemen settled in Manx-land and it is of rather outstanding interest to find among the records of the Manx Museum, Douglas, a description of the Nordic water wheel developed, then, to such a high pitch as to possess radial blades in lieu of the angular buckets adopted by the vertical waterwheel. This shows that the advanced type of Nordic wheel was an original invention pure and simple and hardly a horizontal edition of a vertical wheel that no one had, as yet, seen.

The originality of the type is further proved by a writer of olden days comparing the blades to "ladles" which at once reveals them as helical blades and as such a highly intelligent anticipation of the modern horizontal turbine.

As if this were not enough the later patterns of the type had tentering gear by which the runner stone was capable of being raised or lowered in relation to the bed stone so as to vary the degree of milling, or "reduction" at will.

This, like all great inventions was simplicity itself. Instead of the runner stone being fixed to a wooden shaft set vertically at its lower end in a "footstep" bearing of stone, this bearing was set in a baulk of timber, probably elm from its water-resisting properties. The baulk of timber was pivoted horizontally and provided with a projecting handle. So all that was required in this case was to heave down on the handle and to thus lift the runner stone to the required height and, therefore, working clearance.

As no further details are forthcoming it may be taken that the miller, having obtained the required degree of "tentering" slipped a wooden gauge between the stones and made all fast by one or two, probably three from the centering point of view, wood keys. We may infer from this degree of care and the obvious urge to excel that these millers were "in the trade", and were out to beat their competitors not so well equipped.

These mills also had the equivalent of the modern "damsel" as the feed from the hopper to the "eye of the stone" was automatic, and practically noiseless. In operation the hopper was slung from the roof by two ropes, the oscillating movement being provided by a "crank pin" standing vertically up from the stone and linked to the lower end of the hopper by a loop or bridle of cord.

This idea very probably came from the hand quern in which the runner stone was provided with a vertical handle for manual opération.

And now to stretch these extremes still further.

Laxey, on the east side of this island, measuring 28 miles by 12, possesses the largest and most unique overshot water-wheel in existence. That is a wheel of modern design and built under the most unusual conditions and upon an extraordinary site,

There is reputed to be a Syrian waterwheel 75 ft. in diameter, but this, if still existent, is of the poncelet or "surface" type and roughly put together of wood.

Fig. 1 [Laxey Old Mill]

Just before reaching the Great Wheel Laxey the writer encountered the next extreme, as shown at Fig. 1, an ancient grey old stone mill with its modest 10 ft. overshot wheel. And, a few hundred yards away, on the hillside, the Laxey Great Wheel in all its pristine glory, externally at any rate.

Fig .2 [Lady Isabella Wheel]

At Fig. 2 we see the full 75 ft. 6 in. of its majestic diameter and it is still able to turn on "occasions". The wheel was completed and set going in A.D. 1854. A Press-man of the time refers to the wheel as of the "breast type". This is, of course, incorrect as a glance will reveal that it is of the overshot, "pitchback" type, i.e., the water impacts at 11 o'clock instead of the more usual 12 o'clock and the wheel therefore, runs against the stream and not with it. The water actually comes up through the stone column by a 24 in. pipe, the tube forming a "U" as it descends from a mountain lake, crosses a valley and then rises to the top of the tower.

The main shaft weighs 10 tons and is 21 in. in diameter. It was a case of urgent necessity that prompted so great a piece of work. The Laxey lead and silver mine was threatened with permanent flooding and as steam was out of the question, water was the only possible power. And here it was on the site. The greater part of the foundry work was carried out at Wigan with some of the minor parts produced at a foundry in Douglas.

The actual site of the wheel is far from the pithead so the pump "rods", baulks of oak some 18 in. square run up the valley for 600 ft. being mounted upon flanged wheels set on a railtrack supported upon noble stone arches. The pump rods proper were attached to a huge bell crank lever the pump itself being at the bottom of the mine.

The crank pin is connected to two beams the one linking up with the pump, being supported with a radius rod the other is linked up to a bell crank to which is attached a wooden tub steaded on guides, the tub being originally filled with weights to balance the combined pull of the pump and the 600 ft, of wooden rods.The wheel was christened "Lady Isabella" on the occasion of opening day, but has long, long since been known as the "Great Wheel Laxey" by the local folk, The pumping depth was originally 1,200 ft. output, according. to the Pressman of the time, being 250 gallons per minute, This representing 3,000,000 ft.lbs, suggests some 100 horsepower theoretically, but the great length and cumbrous nature of the "power transmission" must have cost the installation a loss of the order of 50 per cent.

Fig. 3

The main structure of the wheel follows usual practice in being built up of cast iron segments bolted together: but, this is not enough as the wheel is strung with a large nurnber of tension rods which gives the inside of the wheel the appearance of a gigantic cycle.

The close-up of the wheel, seen at Fig. 3, shows the rods also the crank and the two beam members. the weight being taken by the two massive cast iron stanchions.

Manxland being hilly and abounding in small water power and moreover, being self-reliant to the point of near self-support, it is not surprising that small milling enterprise flourishes and, incidentally, reveals much that is unusual to the investigator from the mainland.

Fig. 4 [Glenfaba Mill Wheel]

As an example take the mill at Glen Faba; a glance at the wheel of this mill, Fig. 4, reveals at the forward end a stone building ventilated by louvres and surmounted by a cowl.

This is a kiln in which oats, all locally grown, are heated over a fire of coke. corn husks and the like for some two hours before milling, The wheel is some 6 ft. diameter breast shot with an 8 ft. head the mill water being peculiar to the mill and being taken from the River Neb through a run back to a fall a mile up stream.

The power transmission here is out of the ordinary as it consists in the first place of a 3 o'clock spur pinion driven from a spur wheel on the water wheel, the horizontal shaft running almost the length of the floor and bearing five bevel crown wheels meshing with bevel pinions which slide on the stone shafts both for tentering and putting the stone drives in and out of gear. So far as the writer knows the term "tentering" is unknown on the Island the miller referring to the operation as "setting". Another term not used applies to the "thrift", i.e., the shaft in which the mill bill is held during the operation of stone dressing.

Another interesting feature is seen in the mill being of two buildings some 20 ft. apart, a covered way just under the eaves housing a sack hoisting chain complete with control cord so that the one sack tackle is available to both sections. A complete threshing machine is also installed, an excellent dynamo of about ½Kw providing light also power for battery charging, the latter well protected by an automatic cut-out together with the necessary instruments. Upon the writer commenting favourably on the installation the miller agreed that: "it ought to be all right as I gave £4 for the lot"!

Up on the stone floor the oats are milled, elevated and passed down to the sifter which also contains a winnowing fan to remove all husks, any oats not properly milled being returned to the stones. The Manx name for the portion of grain retained by the miller as "grist" is known as the "malta" a term of ancient and obscure origin. This very versatile and enterprising mill also turns out barley meal, pearl barley, rye meal and groats.

Editor's Footnote: This article first appeared in Power Transmission, to the editor of which we are grateful for permission to reproduce it.

|

|

||

| Water powered Mills etc | ||

|

|

||

|

Any comments, errors or omissions gratefully received

The Editor |

||